Overview

- Meta-materials, constructed from lattice structures, offer vast design freedom suitable for high-performance applications. However, the limitations of current tools to predict their properties often constrain the design potential.

- Physical testing of Meta-materials to find their properties is not scalable. On the other hand, simulation-based approaches face challenges due to bottlenecks like meshing and other preprocessing steps.

- With Intact.Simulation, meshing and geometry simplification become unnecessary. Its speed and automation enable designers to explore a broad parameter space for Meta-materials, facilitating the discovery of more optimal and innovative materials.

Automate design space exploration of lattices with Intact.Simulation

This blog demonstrates the use of Intact.Simulation to automatically find the mechanical properties of gyroid lattices for a wide range of lattice parameters.

Create and homogenize Gyroid-like structures with offset

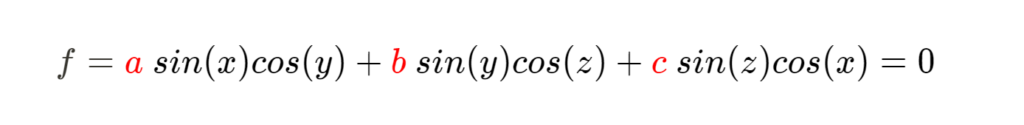

In Rhino/Grasshopper, a Gyroid-like surfaces can be created using the Axolotl plugin. The formula for a gyroid-like surface is given by the following equation

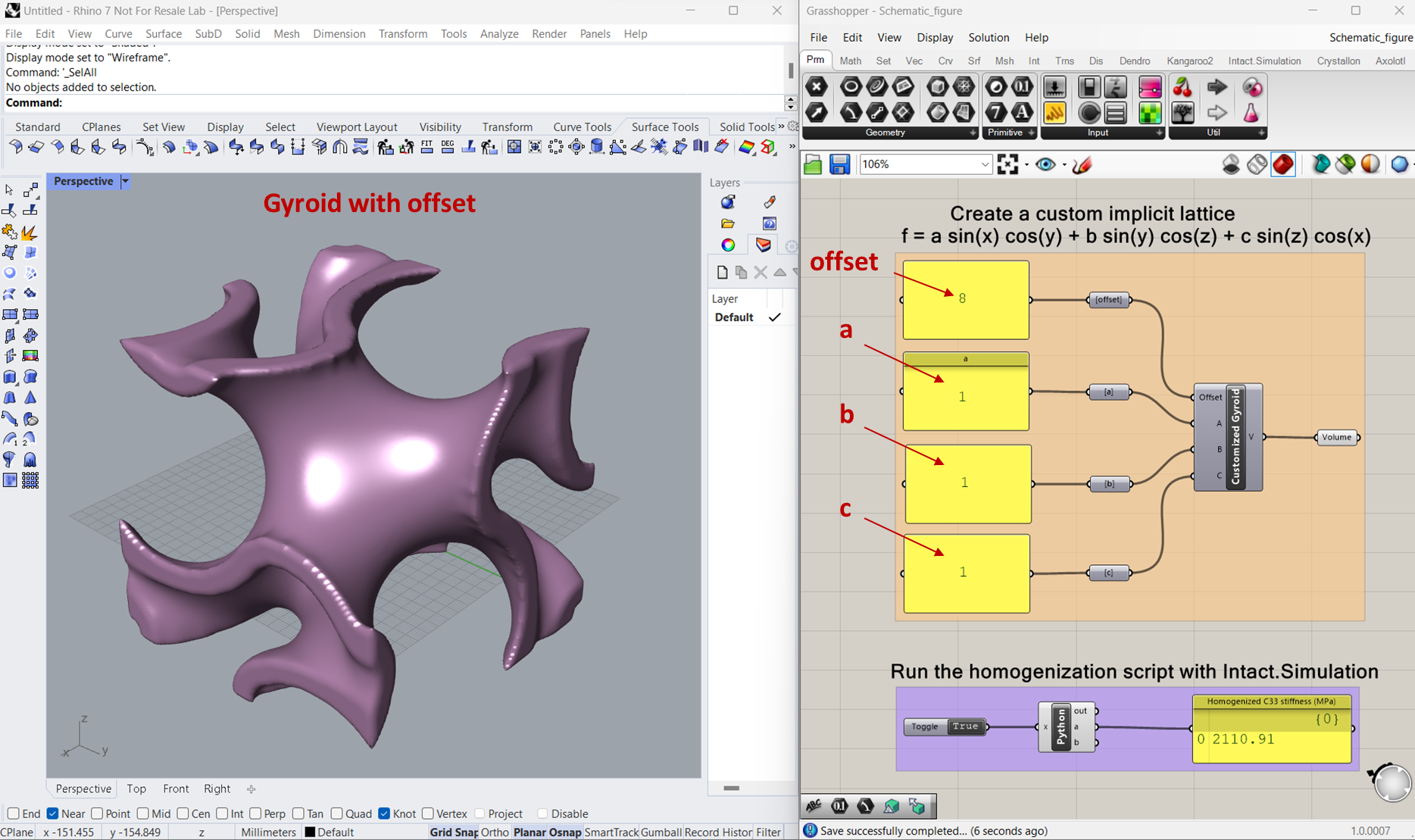

As shown in the picture below, the gyroid-like surface can be offset (using Dendro) to create a solid lattice structure. Users can interactively adjust the values of a, b, c, and offset to generate gyroid-like lattice geometries, and simulate the homogenized properties (e.g. stiffness in z direction, or effective Poisson’s ratio) using Intact.Simulation in a single automated workflow.

Automate computation of homogenized stiffness of lattices with Intact.Simulation and Python

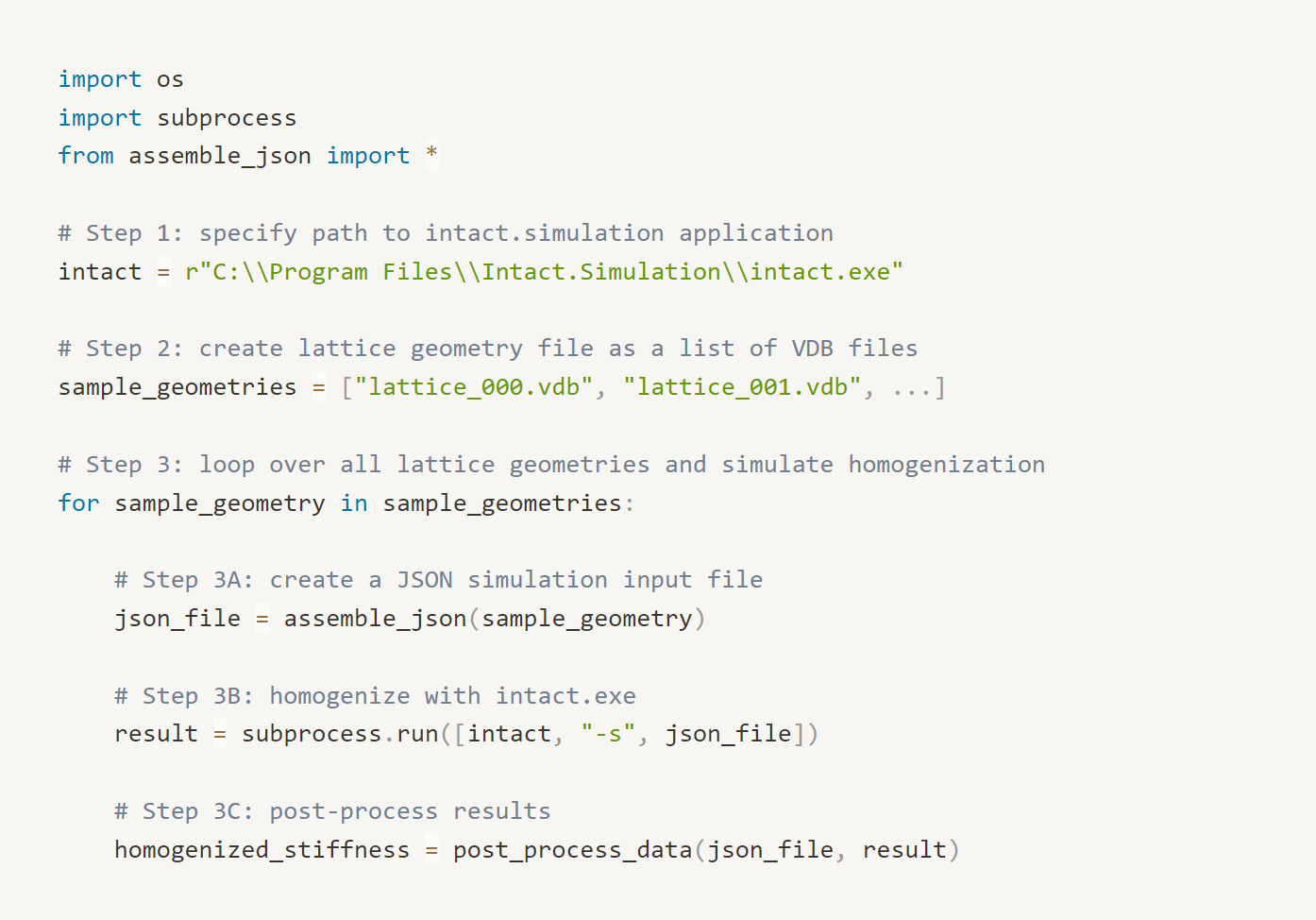

With Intact.Simulation, users can perform a design space exploration in an automated way. For instance, users can perform a design sweep—where they can study how the coefficient a affects the homogenized stiffness in the z direction. A simple python code as shown below should accomplish this.

The results of the design space exploration are shown below, where the z-stiffness (Ez) is computed for different values of a ranging from -4 to 4, and b=c=1 As we can see from the video below, values of a close to 0 have the lowest values of stiffness, and the stiffness value increases as |a| increases. Interestingly, the graph of stiffness vs a is symmetric about the y axis.

With Intact.Simulation, you can run automated simulation in a loop with no manual intervention, empowering your design applications and unlocking the innovative and more optimal materials and designs.

✅ No preprocessing and meshing bottlenecks

✅ Simulate native representations without conversion

✅ Seamlessly integrate to your design workflows

Without any meshing, preprocessing, or human in the loop, Intact.Simulation scales to predict the mechanical properties of thousands of meta-materials.

Discussion: Effect of a on stiffness: an intuitive explanation

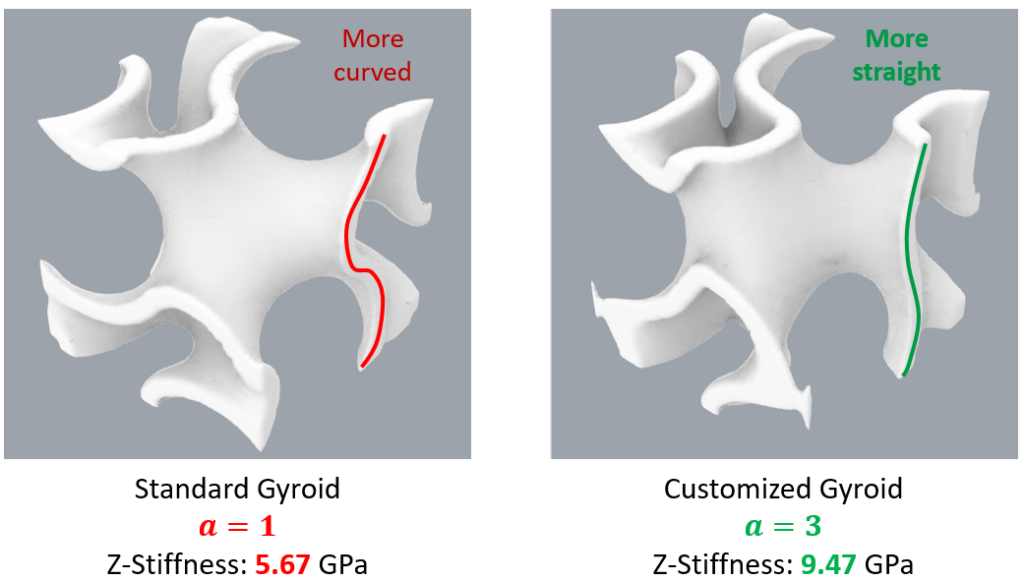

The figure below shows two gyroid-like geometries, with the one on the left with a=1 and the one on the right with a=3. As we can see from the figure below that the standard gyroid with a=1 has more curved cross-sectional footprint, as shown using the red line below. The customized gyroid with a=3 has more elongated and straighter (in z-direction) cross sectional footprint, and as a results, has a higher value of stiffness.

How this helps designers choose a lattice structure for their application?

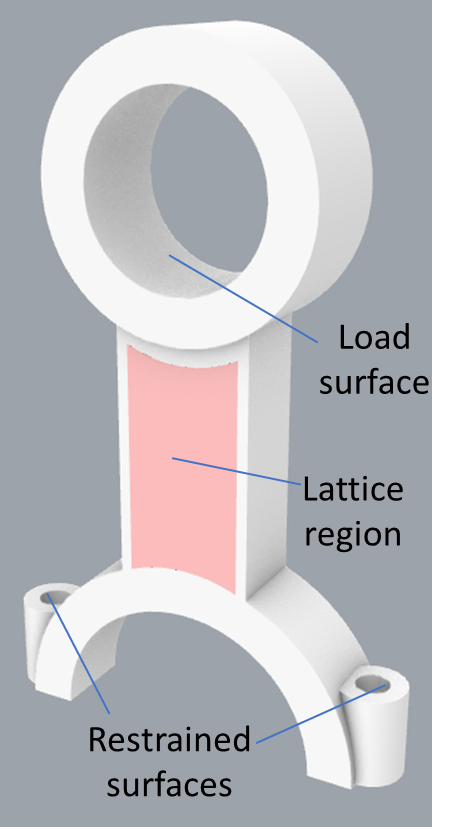

The picture below shows a schematic of a piston rod (adopted from the GRABCAD library) which shows a load surface, with the load applied along the z-direction, restrained surfaces, and the region to be infilled with lattices in pink. So, how does a design space exploration study performed above help a designer choose a lattice?

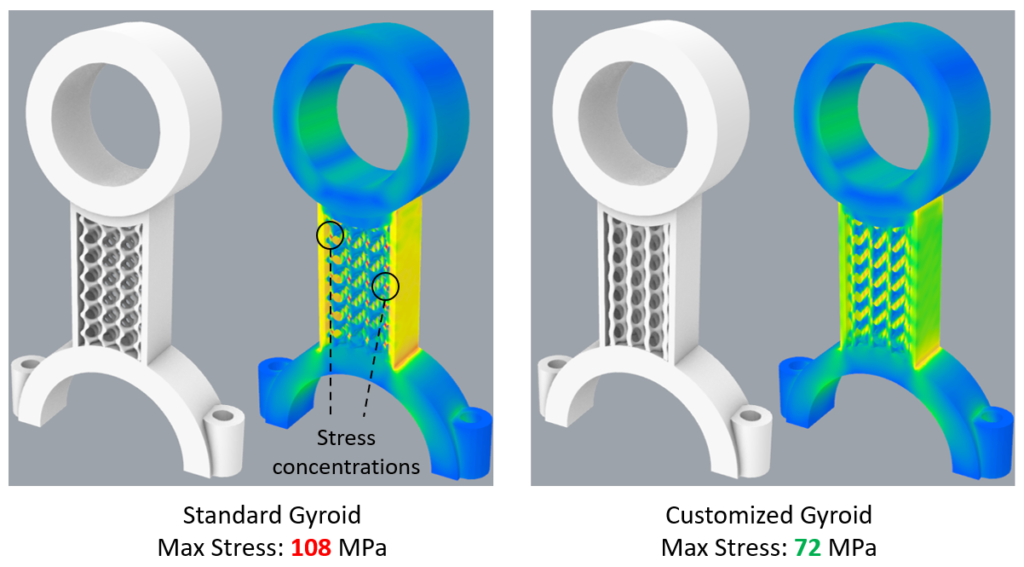

The design space exploration study showed that the standard gyroid with a=1 has a lower value of stiffness compared to a customized gyroid with a=3. Therefore, designers can use the customized gyroid lattices for light-weighting, and quantitatively compute the effects of customizing the lattice on the resulting stress distribution. Specifically, the user can

- create the standard and customized lattices as VDB geometries

- use Intact.Simulation for analyzing VDB geometries

The picture below shows the stress distribution for both the standard gyroid and the customized gyroid. The standard gyroid infill has a lower value of stiffness, resulting in a higher max stress values of 108 MPa (shown on the left). The customized gyroid infill (shown on the right) has a higher value of stiffness, resulting in a significantly lower values for max stresses (72 MPa).

Conclusion

Automated Design Space Exploration using Intact.Simulation allows for the exploration of a wide range of lattice parameters for meta-materials. By automating the computation of homogenized stiffness and using Python, designers can easily study the effects of different lattice parameters on mechanical properties. This automated approach eliminates the need for manual intervention or preprocessing, making it efficient and effective for design exploration.